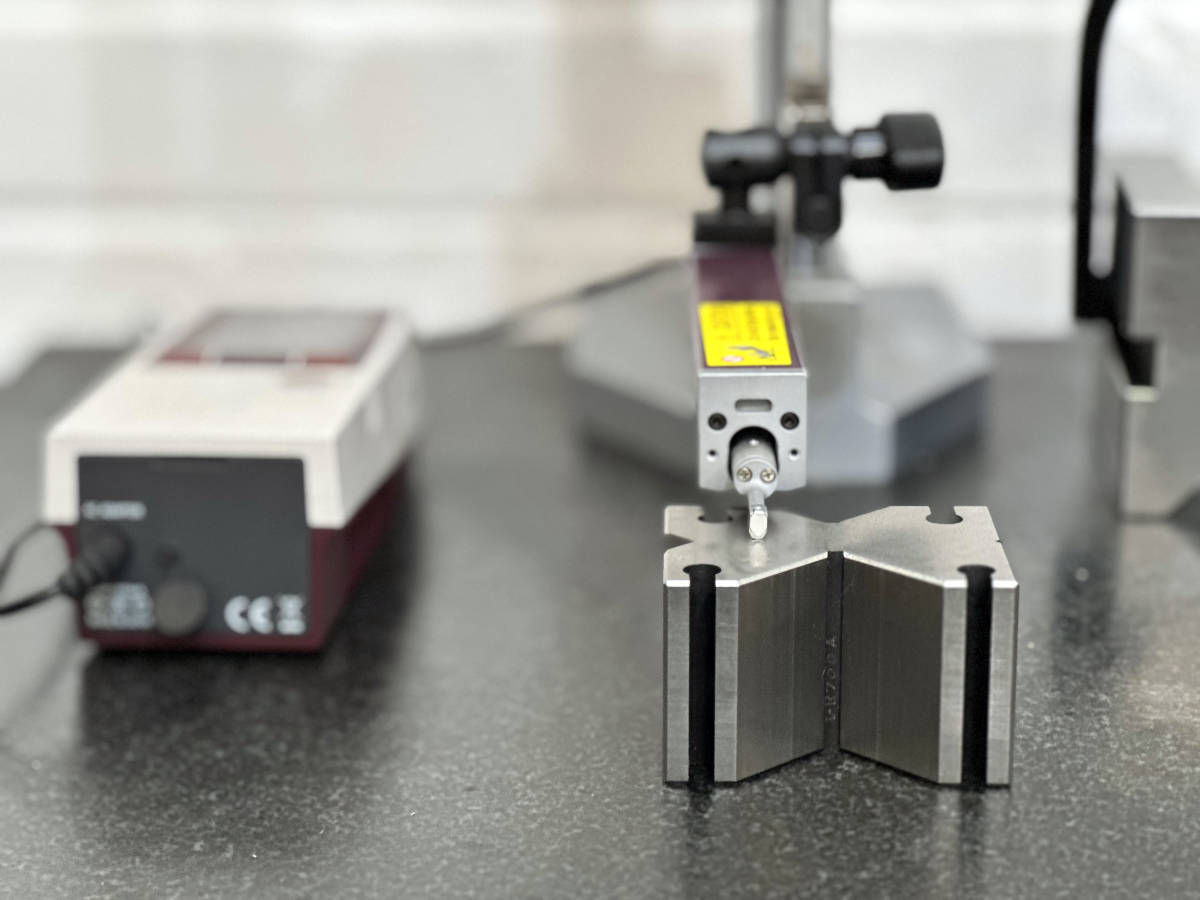

Tips for Higher Quality from CNC Machining Providers

Quality. Everyone wants it but not everyone is getting it. Here we take you through the main things to look for and questions to ask prospective machining suppliers when it comes to quality.

Explore our Blog articles below

Quality. Everyone wants it but not everyone is getting it. Here we take you through the main things to look for and questions to ask prospective machining suppliers when it comes to quality.

Have you ever marvelled at the sleek finish on your favourite gadgets? This level of finish is achieved from a process that is part science, part artistry. We're talking about plating. In this blog, we take you through what plating actually is, why you might choose plating, the factors that affect the final plating finish, and how you can allow for plating at design stage.

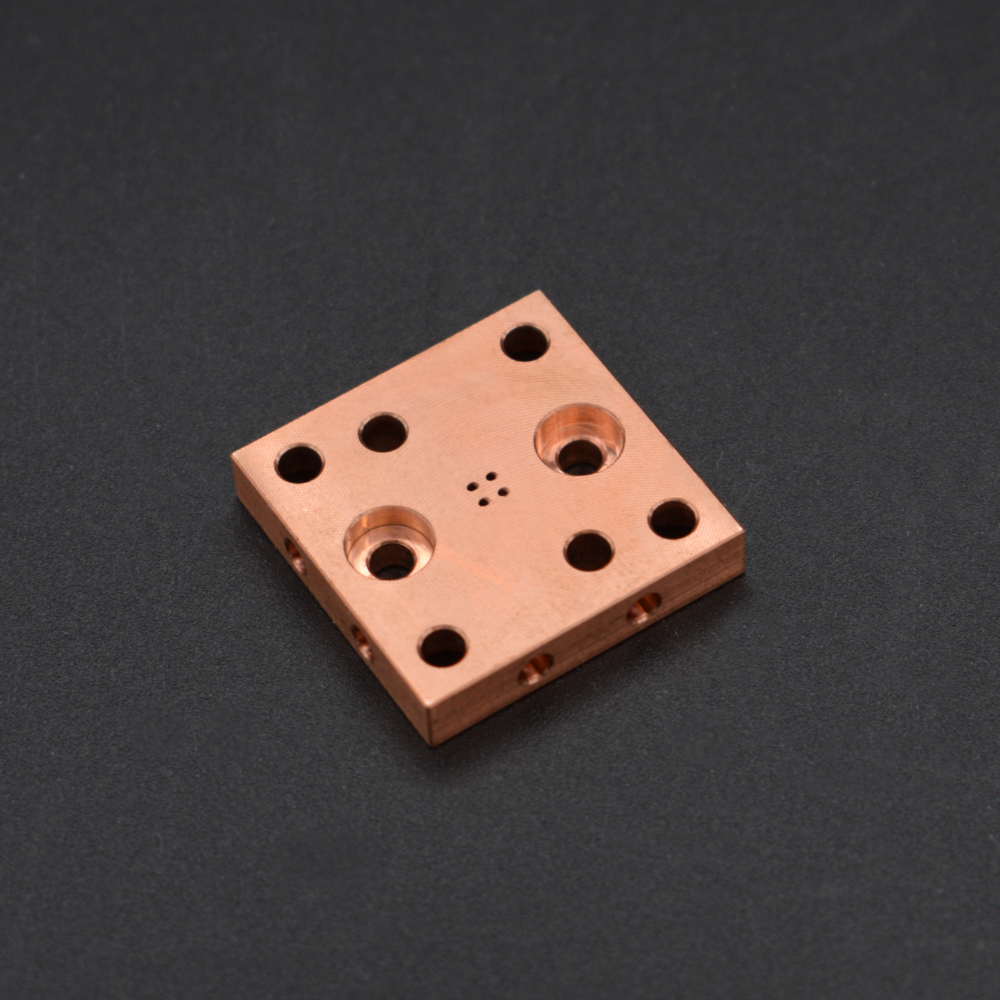

Copper or brass? Brass or copper? If you’re in a quandary about which of these two yellow metals to choose for your CNC machined component, you’re not alone. In this blog we bring you the lowdown on these two excellent options and will help you compare them side by side.

Delve into the essentials of surface finishing and explore the five key factors every specifier and engineer should consider when deciding on the appropriate surface finish for their CNC machined part.

Reshoring is becoming increasingly common. There are lots of benefits to moving your production back to the UK. Take a look at our top four reasons to reshore the manufacture of your precision machined components.

From the arrival or 17 new team members, investment in 2 new machines for our workshop to being shortlisted for 2 business awards and climbing to the summit of Pen Y Fan - it's been some year! Our latest blog reflects on a busy and productive 2023 for the Penta team.

If you're trying to get a component within a specific budget, consistently getting quotes that are just too high is going to cause you problems. Here are a few tips on how to optimise your design and get your component in budget.

Delve deep into the art of threads design, manufacturing, and more. In this blog we explore in detail how to select and specify threads for CNC machining as well as draw your attention to key design considerations. We also take you through how Penta machine threads to give you more background for your design.

It's all too common. At the start of a relationship, everything's rosy. But then you take the next step... and bam. You've been ghosted. What next?

In this blog, we take you through what might be a familiar situation when it comes to communication from your CNC machining supplier, what the horrifying cost of that might be, and how you can improve communication with your existing or new supplier.

![]()

EXPLORE

![]()

EXPLORE

![]()

EXPLORE

__________

On a mission to become the engineering company where everyone wants to work and who everyone wants to buy from

Penta has developed a system that enables us to deliver quality parts to our customers; ensuring the same level of service to all, irrespective of where you are based in the UK.

__________